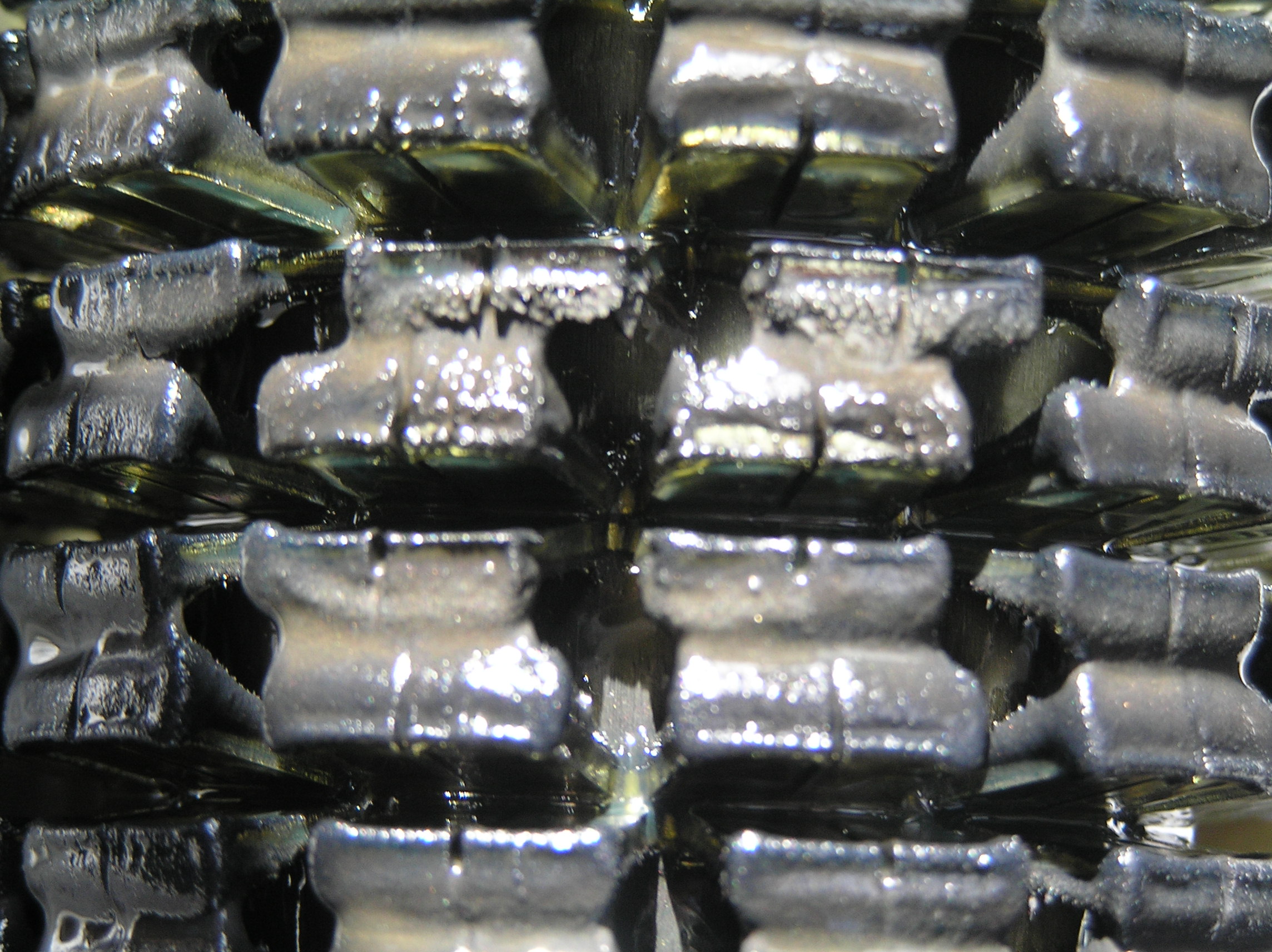

Actual build up after 3 days in use

“Amazing results in three days”

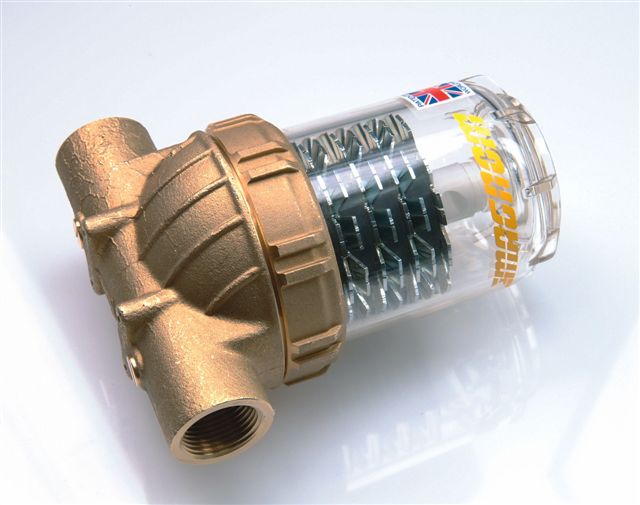

A large ferroalloy smelter has introduced the Magnom Filtration System to a large gyro crusher gearbox lubrication circuit.

Previously, the gearbox had experienced a major and expensive failure which unfortunately hadn’t been detected. In this case, the lubrication system had been filtered via conventional filtration.

This failure was a significant disruption to the production of the process because there were limited parts available to carry out the repair quickly.

The company decided to try the Magnom 5” Clear instead. And, after only a few days of operation, were very surprised to see the amount of contamination it collected.

As you might imagine, this level of contamination was not expected, and further evaluation of the reconditioned gearbox was required.

This has led to other applications now being reviewed for installation.

The benefits of installing this filter technology include:

- The capability of removing large volumes of contamination without flow restriction

- Removal of ultrafine particles (less than one micron) from the lubrication system

- The improved lifespan of the oil and existing filtration

- Extended lifespan of the gearbox

The company now can monitor the condition of the gearbox and determine any future problems.

Contact us for more information about the Magnom Filtration System.